Russian brand Green Cone Retail (GCR)

Green Cone Retail is a Russian trademark registered in the international system and the World Intellectual Property Organization (WIPO).

All Green Cone Retail (GCR) factories are certified with the ISO 9001 quality management system and daily produce flawless quality products in line with the company’s culture and strict standards.

Inspired by new ideas, GCR closely monitors modern trends. With this in mind, GCR’s research and development department designs and, after rigorous testing, offers customers innovative and useful products.

Expanding its partner network, GCR has opened offices in Uzbekistan, Belarus, China, Kazakhstan, and Armenia.

The core principle of GCR is to work day after day exclusively in the interests of all humanity. This implies not only caring for customers and partners but also taking responsibility for the impact that the company's activities have on the environment. GCR strives to protect nature by taking measures to reduce the negative impact of its products and production processes on ecosystems.

An important aspect of this principle is enhancing comfort in the lives of every individual. The company develops and offers technologies and solutions that make everyday life more convenient and efficient. This applies both to the quality of the products themselves and their contribution to creating a comfortable environment—whether at the workplace, in educational institutions, or at home.

Thus, GCR is purposefully moving towards achieving a balance between the needs of humanity and the care for our planet, creating technologies that not only simplify life but also promote its sustainable development. The commitment to integrating these values into its activities makes the company a key player in addressing modern environmental and social challenges.

Since 2014, GCR has been actively expanding its product line, which includes chargers and accessories for mobile phones and computers, as well as automotive accessories. GCR's product range features a variety of computer and digital cables, including HDMI splitters and matrix switches that provide convenient connection and distribution of video and audio signals. The assortment also includes HDMI extenders, which allow signal transmission over distances of up to 200 meters while maintaining high-quality image and sound over long distances.

GCR focuses primarily on the development and production of mini-computers (miniPCs) and nettops, as well as OPS modules for interactive panels and high-quality LED and OLED displays. The company aims to create reliable and efficient solutions for various sectors, including education, business, and entertainment. These innovations enable GCR to remain at the forefront of technology and offer partners products that meet modern requirements.

To date, Green Cone Retail has established an extensive distribution network that combines both online and offline sales channels. We take pride in being able to offer innovative and high-quality products that meet customer needs. The R&D department continuously works on improving and adapting the product range to keep up with the dynamically changing market demands. We are confident that GCR's products make a significant contribution to enhancing user experience and improving the efficiency of our partners' operations.

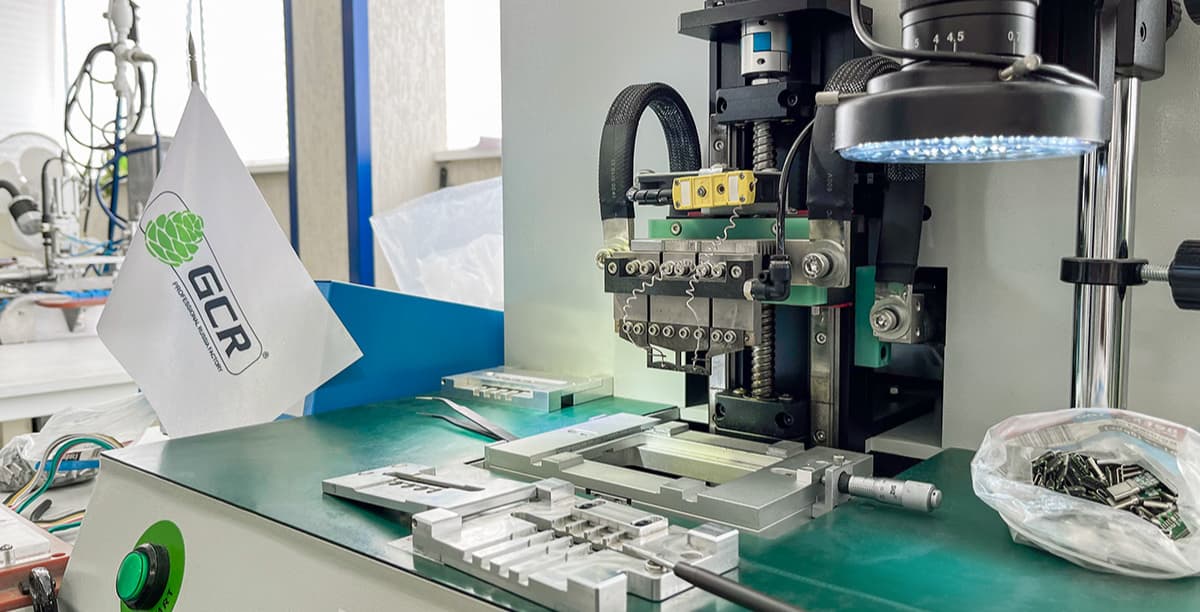

Since 2019, the production of the Green Cone Retail brand has been organized in Russia at the facilities of PZKMK LLC, with the aim of creating high-quality products that meet the most stringent standards. The focus is on modern production equipment, which ensures process efficiency and a high degree of automation, reducing the likelihood of errors on the production line.

One of the core values of GCR is the high quality of components used in production. The quality of materials is controlled at all stages, including before being introduced into the production process. This guarantees that every component used in the products complies with strict Russian and international standards.

Professional employee training also plays an important role. The qualifications and expertise of the team are key factors in achieving successful results. Investments in development and training are made through regular workshops and seminars, enabling employees to stay up to date with the latest technologies and industry practices.

Every step of the production process is closely monitored, from the incoming inspection of components to the final testing of finished products. Such meticulous attention to each stage helps ensure that the final result meets customer expectations and provides a high level of reliability.

Special requirements for components, careful selection of raw material suppliers, professional training of employees and utmost attention to every step of the production process and the final result - all this is inextricably linked to achieving high quality of manufactured products.

work

daily

of various configurations

groups

GCR offers both connecting and transition optical patch cords. Each manufactured product undergoes multi-stage control at all stages of technological operations, meets the specifications and requirements of world quality standards for direct and return losses, radius of curvature, tip apex offset, fiber end position in the tip, resistance to mechanical and climatic influences. The outer sheath of GCR optical cables is made of low-smoke and halogen-free LSZH compound, providing a high level of safety for use indoors.

A powerful production fleet of machines designed to create USB cables allows us to produce thousands of units of various types and configurations daily. Automation is an important aspect of the production process, minimizing the likelihood of human errors and improving overall productivity. Each stage from soldering to final testing is filled with innovation and strict quality control, guaranteeing high quality and reliability of the manufactured products.

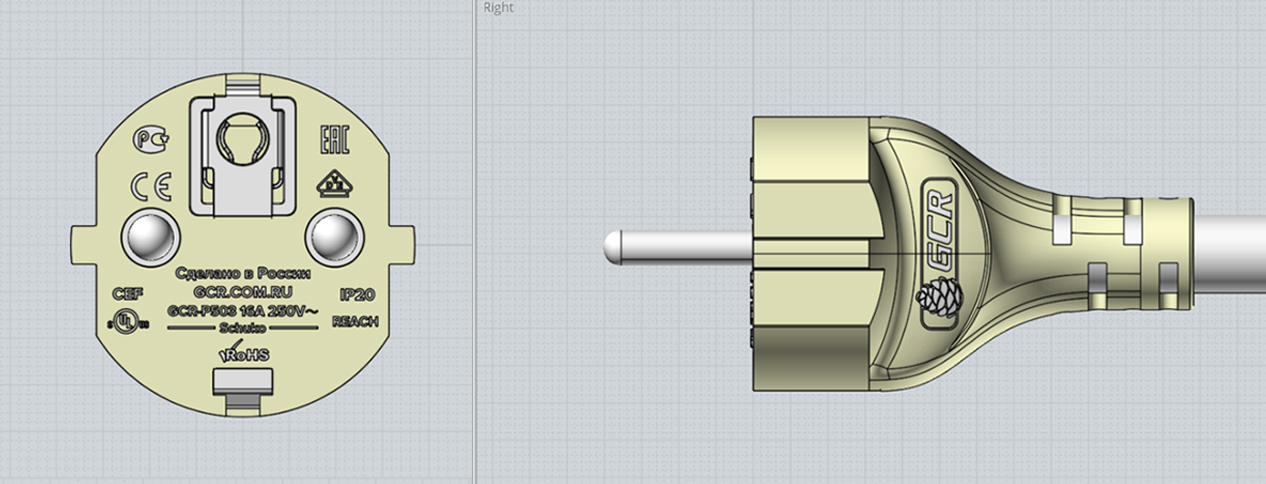

The in-house R&D and design department of Green Cone Retail (GCR) is responsible for the creation of new products — from concept to the launch of mass production. The department's specialists are engaged in development, design, 3D modeling, prototyping, and the creation of molds for the first experimental samples.

To achieve the best results in design, 3D printing and the production of silicone molds for working with various materials are used. The department also specializes in the development of small-batch products for manufacturers of various types of equipment and machinery.

GCR pays special attention to warehouse organization and logistics, striving to ensure the fastest possible delivery and movement of goods.

The PZKMK warehouse is equipped with modern storage systems, which allows for efficient sorting, storage and tracking of goods in real time, ensuring prompt order processing and maintaining a high level of service.

The branded packaging reliably protects the goods during transportation and is an excellent marketing tool, making the products easily recognizable and strengthening their position in the market.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)